Strength Display

QinSheng Mould is really a manufacturer of complex molds focusing on household goods, household appliances molds, automotive plastic parts molds。

STRENGTH

In line with the principle of being responsible for the design and production of each step, we have achieved satisfactory results step by step.

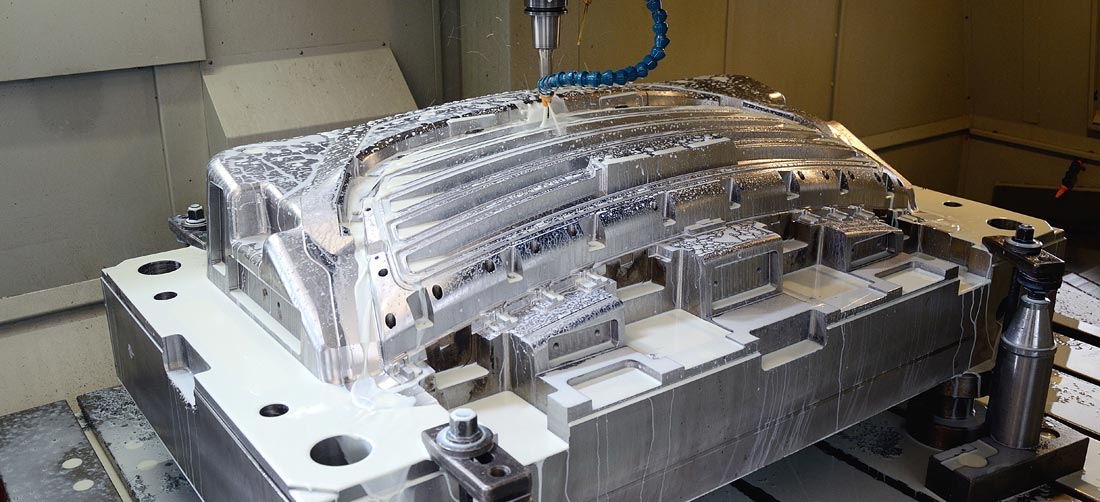

Qin Sheng mold company attaches great importance to the renewal of machinery and equipment. Our factory currently has more than 20 kinds of die steel processing equipment, such as CNC machine tools. We have the high precision Taiwan Gaofeng brand. Double ended EDM is not only efficient, but also can use large mold. High-speed engraving machine can ensure the rapid processing of molds and high-precision processing, but also more expensive than ordinary engraving machine. The die assembly machine can assemble large dies instead of manual ones, so as to get higher quality moulds. On the other hand, we have seven Haitian injection moulding machines of all sizes for mold testing to check that the mold is working well. We install machines according to specific products and install the latest camera system to monitor each part.

- Mold technicians should carefully inspect the appearance, cooling system and assembly process of the mold according to the company standards and customer standards.

The company can provide product analysis and Mouldflow reports, and give customers timely feedback on problems found on the drawings, such as thin areas, shrinkage marks, weld marks, porosity, undercut, gate location, gate type, etc. After the design is completed, we will inspect the mold strength, circuit, cooling system, interference area, thickness thinner area to ensure that we provide product design drawings to ensure that the final product has a good state, a longer mold life and work efficiency.

- We will focus on qualified spare parts to meet customer requirements for standard parts models, quality standards and procurement time.

Physical processing will be carried out in accordance with the established process, and the relative inspection will be carried out, strictly checking the core, cavity, insertion, guide post, return needle, angle elevator, slider, thimble, cooling system and connector, and so on. Prepare documents before shipment, such as spare parts list, mold inspection video, process documents, 2D/3D drawings, etc. We will pack and transport according to customer's requirements to ensure the safety of sea and air transportation.

QINSHENG MOULD

Mold quality is the soul of company mold. We have a strong mold manufacturing team and strict quality control policies at all stages.

QINSHENGCreate every pair

with your heart

The way in which plastic is injected into the mold is

oftenimportant in determining the quality of the .

-

Meeting customers' needs It is the final goal of Qin Sheng mold, striving to be precise and perfect in details.

-

Qin Sheng's engineers are experienced in design. Comprehensive development concept.

-

Qin Sheng mold will be CAD/CAM/CAEAnd other international

advanced computer design system

EQUIPMENTProcessing capacity

Committed to providing customers with more advanced, more reasonable, more precise

quality molds.

-

The company has introduced world-class mold manufacturing and processing equipment, dedicated to providing

-

All the operators of the company need to be trained to qualify before they can go to work, and regular retraining

-

The mold is completed through machining center equipment, all processes need self inspection.

QUALITYQA ABLITY

QC team is set up to supervise every production of mould. Process ensures product quality first!

-

Customers only need to provide DXF, DWG, PRT, SAT, IGES and other formats of two-dimensional or three. We will scan the sample and produce the product blueprint. After confirmation, the mold assembly and drawing design can be carried out according to the customers' existing items.

-

The company has perfect quality management system and system. In daily work, the company pays attention to strengthening the quality awareness of employees, and organizes regular monthly special training and improvement on quality defects and other issues.